Comparing Standing Seam vs. Screw Down Panel for Metal Building Roofs

Do you want to design and install a metal building with metal roofing that will last up to 50 years? When you design a building with metal roofs, you have to consider the site of your building, create or buy designs, and get approval. Of course, you can then put the finishing touches on your purchase by choosing between a standing seam metal roof and screw down metal roofing. The screw down and standing seam roofs are important because they are each designed to offer different strengths and advantages.

Comparing Metal Roof Systems: Standing Seam vs. Screw Down Panel

Both standing seam and screw down panel metal roofing systems have a place in the industry. You'll see in the following sections that standing seam and screw down panel roofs have differences in their installment, function, and format. This makes some customers choose standing seam roofs for some spaces, and others pick screw down paneling.

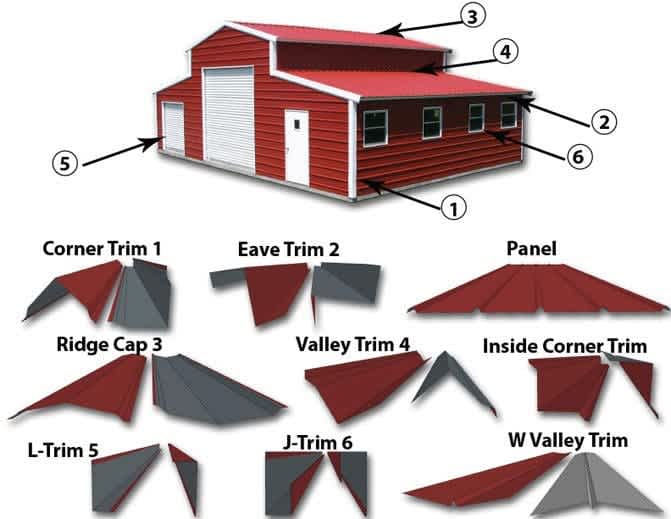

- Standing Seam Roof:A standing seam roof system includes panels with a broad, flat area between two ribs or fasteners. The mechanical connection between these seams stays hidden and sits between 12 and 24 inches apart on the structure. This system grows in popularity because of its weather-strong qualities, sleek look, and lifespan.

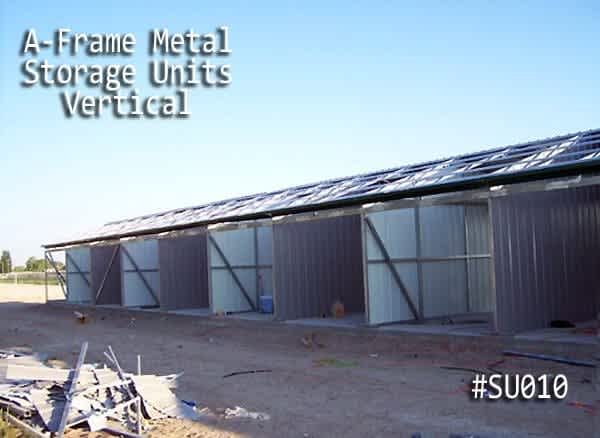

- Screw Down Panel:A screw down panel roof system has similar panels that are screwed in through the face of the metal to fabricate the roof. These connections are not hidden or sealed with another mechanical seam structure. Customers use this system to cover carports, garages, porches, barns, and anywhere that might not be a living or workspace that requires more advanced roofing.

!Comparing Standing Seam vs. Screw Down Panel for Metal Building Roofs

Standing Seam Panel Roof System Benefits

The standing seam panel roof system immediately offers hidden fasteners that sit outside the building envelope, providing better weather and wind resistance under various roof and loading conditions. In addition, the seaming method of this system ensure that your roof will function properly at the lowest possible cost. The system remains one of the easiest to install and depend on for cost-efficient projects because it's designed to work in a variety of complex building situations.

!Comparing Standing Seam vs. Screw Down Panel for Metal Building Roofs

Screw Down Panel Roof System Benefits

Screw down panel roofing can be useful for short-term and non-living or -working spaces that require a quick solution. This means that for barns, sheds, covers, and others, you can install a roof easily by simply screwing in panels directly through the metal. While this solution may not be as permanent as a standing seam, it does offer the convenience and simplicity of an effective roofing system to the customer who only wants the most basic cover.

Standing Seam vs. Screw Down Panel Smackdown

Standing seam panel roof systems and screw down roofing offer different advantages and disadvantages to any metal building project. Here, let's consider the expansion capability, maintenance, oil canning, and cost of the systems. Get a better idea of our standing seam vs. screw down panel comparison and choose the right roof for your metal building project.

Expansion Capability

Every roof expands and contracts with the temperature and weather conditions. For the most part, roofs concern thermal expansion, and standing seam panels allow such expansion freely. On the other hand, the screw down method does not factor in expansion and leads to screw holes widening for repair within 10 years. In short, only through standing seam roofing can you allow natural expansion and durability in your metal roofing.

Maintenance

As a result of superior construction, standing seam roofing systems require almost no maintenance. Despite cleaning and replacing boots and collars, these mechanically locked panels will ask little of the designer or builder. Unfortunately, the same does not support the screw down roof, which will eventually lead to screw holes, leaks, and the need for regular roof maintenance. In general, you would need a contractor every five to 10 years to replace and repair screws causing holes or tears in the roof.

Oil Canning

Since roofs expand, oil canning forms from tightly held standing seam panels, not being able to expand sideways, causing bubbling in your roof. While bubbling is a purely aesthetic problem for some that have little to do with functionality. If you ensure your panels are not seamed too closely together, you can avoid oil canning, which doesn't appear for screwed down roofs.

Cost

A standing seam metal roof requires a thicker gauge of metal and a skilled craftsman for installation. This makes the labor cost and the material cost go up, which makes a standing seam metal roof cost more than a screw down metal roof. Yes, upfront you're going to pay more. What you need to ask yourself is if almost zero maintenance and peace of mind for the next 50 years is worth the extra money.

Bottom Line: Choose Standing Seam Roof System

By looking at the costs, risks, benefits, and disadvantages of these roofing systems, you'll quickly see that standing seam roof systems are the better option for living and working spaces. If you don't mind expensive maintenance every five years from screw down holes and leaks, you might choose the quickest, cheapest option for your barn or shed. But, if you want a roof that will last years while minimizing the cost of building maintenance, you will likely choose the standing seam.

The Best Metal Roofing System for You!

You now know how these two common roofing systems for metal buildings work, how they compare, what they might cost, and which you should choose for a lasting metal building. Coast to Coast Carports manufactures the highest-quality steel buildings with great customer satisfaction and free, fast delivery. They offer 20-year warranties and massive metal building expertise to help you choose the perfect plans and materials. Contact qualified and trained design consultants from Coast to Coast Carports today at (866) 681-7846.

Get Your Custom Building Quote in Just a few Clicks

Select Your Building Requirements

Your Contact Details

Explore Similar Articles

Did you know that your metal building could increase the overall spread of disease or virus? While it may seem insane, it’s true. A prime example would be the recent outbreak of COVID-19, also known as the Coronavirus.

That is a question many of our customers ask us and themselves before they make a purchase. We will then reply with a few questions for them.

Metal tubing, panels, trim, and metal channel can be used for much more than just building Carports. Re-roof your home with metal roofing! Build an ultra strong metal fence out of square tubing. The possibilities are endless. If you only need panels, we can do that. If you only need some hat channel, we can do that. Give our sales department a call to find out more.

Whether you've got a business of your own or are just a backyard mechanic metal shop buildings from Coast to Coast Carports give you the space you need. The terrific thing about our metal buildings is that we can make any shop to your specifications. Not everyone needs a shop building to work on

Some business investments pay off for a few years and fade. Others just keep giving back. A commercial steel building falls into that second group. It’s a smart, practical move that makes sense long-term, no matter what type of project you're working on.

In most cases, you can expect to pay between $14 and $18 per square foot for a lean-to structure, depending on size and complexity. These lean-to structures are typically constructed as additions to an already present structure, making them an easy, cost-effective way to change the look and feel of your metal building.

As the second-largest US state, both in land and population, Texas is home to a wealth of industrial opportunities. It boasts a resilient economy, which experienced phenomenal growth through both the 2009 recession and the Covid-19 pandemic.

Every spring, homeowners are forced to account for tall grass, growing weeds, and outright ugly vegetation on their properties. If not handled regularly, these natural forces can transform a gorgeous property into an unsightly mess.

When purchasing a metal building for your home or business, one of the first questions you'll ask yourself is, 'How big do I need my structure to be?' While the question might seem simple on the surface, the choice you make can have a significant effect on your project and its final price tag. Steel buildings come in many shapes, sizes, and configurations, and finding the right one for your needs is crucial if you’re working on a budget and limited building space.

The secret is out– metal buildings are some of the most versatile buildings on the market and are engineered to handle some of the toughest jobs out there. As more and more Americans choose to invest in steel buildings for their homes, businesses, and farms, the demand for these prefab metal structures has grown exponentially.

Sometimes, you don't always have the luxury of a large backyard. In a world where space has become limited, many individuals struggle for space. But with a metal shed from Coast to Coast Carport, you can enjoy a high-quality structure that makes excellent use of your limited space.

When constructing a metal building, one of the biggest questions you'll ask yourself is whether to install insulation. If you expect to use your structure as a livable building or for anything other than simple storage, you'll likely need insulation.

No matter if you're part of the industry or have just heard about it, real estate is a rapidly growing business. And when industrial land properties are being maintained properly, they can produce quite a sizeable amount of money from one month to the next. While there are certain risks involved with the industrial real estate market, the advantages outweigh the disadvantages in the long run.

In most cases, you can expect a 30x40 metal building to cost between $20,000 and $40,000, depending on the manufacturer you go with and the customization options you choose. There are many metal building providers out there, all with varying prices and levels of quality.

As the old saying goes, a structure is only as good as the foundation on which it stands. And steel structures are no different! Despite these buildings being engineered for strength and flexibility in the face of high winds and heavy snowfall, if your foundation isn't up to snuff, you will have major issues for the life of your building.

If you’re building in a commercial space, there are many facets that you’ll need to cover, and one of those will undoubtedly be insurance. The rates charged by insurance companies will often vary based on the nature of the structure in question. Buildings constructed from materials that are more resistant to the leading causes of property damage will, on average, pay less for their premiums.

E-commerce giants are responsible for storing and moving huge amounts of inventory daily. To accomplish this, warehouses, fulfillment centers, and transportation hubs need ample amounts of unobstructed square footage to house inventory, equipment, and work vehicles.

Metal buildings are a popular choice for many businesses and homeowners. They are strong, durable, and can withstand violent weather conditions and heavy-duty use. But what truly sets them apart from the competition is their customizability. From top to bottom, almost every aspect of these incredible buildings can be tailored to your needs. And one such customization option is their doors.

If you intend to use your metal building for more than just seasonal applications, it’ll likely need insulation. Insulating your structure is a fantastic way to reduce moisture buildup and develop a more even internal temperature. But beyond that, it’s a necessary part of transforming your metal building from a simple shed into something more.

Insulation forms a barrier between the exterior elements and your building's interior. It holds in warmer are during the winter while allowing you to cut cooling costs during the summer months. It also prevents condensation from forming inside your building, which can be a significant issue for sensitive metal components such as fasteners and framing.

No matter what you intend to build, metal buildings have become a reliable construction option that opens up a wealth of opportunities in strength, design, and customizability. This makes them ideally suited for a vast array of applications, from backyard metal sheds to enormous commercial-grade steel buildings.

If you've been searching for the right solution to your storage or infrastructural woes, a metal building might be just what you need. In this blog, we'll explore these buildings in greater detail and show you how to use them to design a dream space that aligns with your lifestyle.

Metal buildings have become increasingly popular due to their durability and affordability. But, while metal structures are known for their strength, they are not always immune to the damaging effects of volatile weather. From spring storms to harsh winter winds, unprepared metal buildings can suffer significant damage if they are not designed to handle changing seasons.

That's why it's important to consider a metal building for sale specifically designed to withstand seasonal changes and weather conditions.

When it comes to business infrastructure, having the right setup is incredibly important. And a big part of that setup will be the design of your floor plan. This floor plan will dictate how you use your business and have a significant say in your productivity and longevity.

When it comes to finding extra space to store your belongings, why not consider using some of the room outside of your house? Installing metal carport kits or metal garage kits is a great way to get the room you need and combine it with a safe space to store your vehicle too.

Both types of kits are a great choice, but there are some fundamental differences between the two that may make one better than the other for your individual needs. Ultimately, metal garages come with sidewalls, a roof, and doors to create a fully enclosed space, whereas metal carports have open sides and a metal roof. If you are not sure which is the best choice for your needs, then we have created this comparison guide just for you – take a look now and then buy the right solution for your needs.

Metal Buildings and Carports come in an extensive array of sizes, shapes, and types. Some are simple outbuildings used to store your garden tools, while others might be large, fully finished homes. But what exactly makes a metal building permanent while others are not? We’re glad you asked!

Any outdoor building directly affixed to an unmoving foundation is classified as a permanent structure. Some examples of these structures include garages, barns, and even homes. Below, we’ll dive deeper into what differentiates these two classes of metal buildings and help you decide what is the better option for your needs.

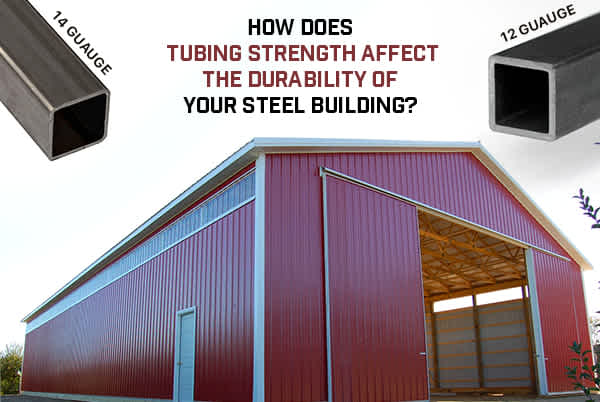

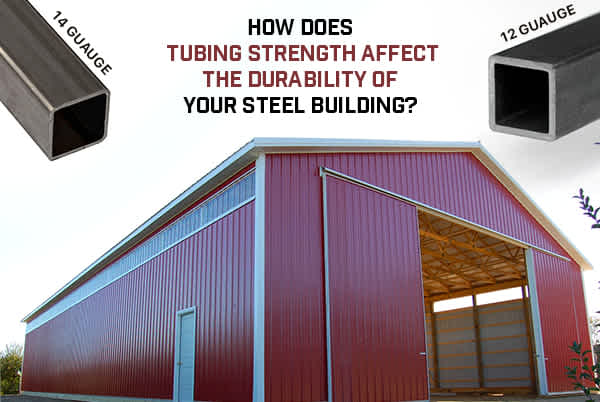

If you’re familiar with gauging, you already know the golden rule – the lower the gauge number, the thicker the material. This is true for everything from pipes to earrings. And this principle is no different when it comes to the frame of prefab metal buildings. But what thickness should the framing on your structure be? Knowing what you need can be difficult if you're not immediately acquainted with steel buildings. So that's why we're here! Let's take a deeper dive into the world of metal buildings to help you find out what you need for your newest building project.

If you’ve ever owned a business, you already know that having the right infrastructure is extremely important to your workflow, finances, and income potential. This is why so many entrepreneurs have chosen steel buildings for their endeavors. These structures are incredibly strong, durable, and built to streamline your functionality.

A well-designed metal building foundation is the cornerstone of a reliable metal building. It serves as the support that holds your building up and an anchor system that holds it down. As such, taking the time to choose the right foundation will dictate much about how your structure performs.

People in Arkansas are frequently subjected to extreme weather, which can cause significant damage to buildings and businesses. As a result of this volatile climate, the region is seeing a growing demand for structures that can survive harsh weather while protecting their valuables from potential damage.

Metal buildings are an excellent option for Arkansas residents that need a structure capable of bearing intense loads withstanding high sustained winds. In this blog, we’ll explore these structures and explain why steel construction is one of the wisest ways to invest in your property.

If you're an avid traveler, owning an RV is an absolute dream come true. But, just like any cherished possession, you will need to keep your home on wheels safe and protected from the elements. That's where metal RV carports come to the rescue! These sturdy structures are a lifesaver, providing a reliable shield against rain, snow, hail, and harmful UV rays.

The beauty of metal RV carports lies not just in their practicality but also in their versatility. They come in many sizes and styles and can be configured to suit your specific needs. Whether you own a compact camper or a massive motorhome, a metal RV carport is ready to accommodate it like a snug blanket.

So, if you’re in the market for a way to protect your investment from harsh weather, UV rays, and potential thieves, keep reading to find out what type of metal RV carport is right for you.

One of the most important decisions you will make in regards to your metal building's design and structure will be the flooring and foundation you choose. For many, this decision comes down to the popularity, durability, and versatility of the foundation. That's why many buyers opt for concrete.

Take a stroll through your neighborhood downtown or retail district. Take special care to notice the buildings the wide variety of architectural styles and the broad selection of materials they use. With such diversity it's clear that you'll have seemingly endless options when it comes time to

Halloween is finally here! It’s a great chance to liven up the office with spooky decorations and the perfect excuse to drag out that old Prince costume. Whether you enjoy the ambiance, the snacks, and candy, or the ingenious costumes, Halloween is, without a doubt, one of the most festive office holidays.

Simply put, you can't go wrong with a 50x50 metal building. No matter the purpose or application, this structure can handle the job. These buildings provide significant space, making them ideal for a wide range of applications. Whether you need storage for equipment and machinery, a workshop for your business, or a spacious garage for your vehicles, a 50x50 metal building can get it done.

Florida is known for its tropical climate and volatile weather. From high winds to flooding, there is no shortage of elemental threats to contend with as a home and business owner. And as a result of the contentious weather, many folks have turned to metal buildings for their infrastructure. These structures are incredibly strong and engineered to handle just about any environment.

In recent years, pre-engineered steel buildings have emerged as an ideal choice for housing data centers, server farms, and cryptocurrency operations. These structures have proven to be a perfect fit for the unique demands of these industries, offering a host of advantages over traditional building materials. From strength to virtually endless customizability, there’s a reason these structures are one of the most popular choices for commercial construction.

In this blog, we'll explore exactly what custom metal buildings bring to the table for Bitcoin mining operations, crypto, and the future of American tech.

‘Clear span’ is an architectural term for the distance between the inner edges of span supports, i.e., the unsupported space. Steel buildings with clear spans offer a comprehensive and transparent surface free from posts and beams. There are no supporting pillars in a straightforward span design, as opposed to pole buildings.

Prefab metal buildings without columns or posts provide the most uninterrupted interior space. Steel buildings with a clear span are the best choice when maximum interior space is needed. Among the possible applications are:

The weather in Texas can certainly pose its fair share of problems. With hot and humid summers, and cold, windy, and dry winters, Texas’s climate is unusual.

During the year, the temperature can range between 36 degrees Fahrenheit and 96 degrees Fahrenheit. With such extremes, it isn’t surprising that the Lone Star State is the state with most disasters. Floods, ice storms, droughts, and tornadoes are all common here, and Hurricane Harvey wreaked havoc on the state in 2017. With all of this in mind, it isn’t too hard to see why a metal building in Texas is such a good idea. Metal garages and workshops withstand the humid, hot climate in Texas extremely well. They also resist natural disasters like tornadoes and hurricanes effectively when compared with other materials. When you need an outbuilding that is built to last, a metal workshop or metal garage in Texas is ideal.

A metal shed is a great way to add extra storage space to your home, farm, or business. These storage buildings come in many different sizes and styles and can be used for a wide range of purposes, from housing your lawn equipment to a workshop for your hobbies and side jobs.

However, before you start shopping for the perfect metal building, you should know a few things to ensure you get the best shed for your needs. So, if you’re searching for the best storage buildings for your needs, this blog is for you! So, let’s dive deeper into steel sheds and cover what you need to know to maximize your buying power!

Metal buildings are a significant investment! And if you're considering building one, you're probably wondering about the costs and how to budget for them. Metal building prices can vary widely depending on several factors, including size, location, and customization options. As such, it can be a challenge to nail an exact price. And even when you can, that price can literally change overnight.

But all is not lost! We can help! In this blog, we'll provide tips and guidance on budgeting for your metal building construction costs, so you can plan and prepare for your project. Whether you're looking to build a steel garage, workshop, or storage facility, these tips will help you make informed decisions and stay within your budget.

The state of Arkansas is a timber-rich region of the southern US that’s home to verdant forestland and gorgeous vistas. The region sits in an area of the country lovingly referred to as "America’s Wood Basket" due to the expansive forest land covering 20 million acres in the state. That’s nearly half of the state’s total land area! And of these numbers, roughly 11 million acres are privately owned by individuals and businesses.

If you’ve ever visited the Lonestar State, you already know that it’s a land of gorgeous blue skies, miles of farmland, and one of the largest economies in the world.

With a massive population and an unparalleled level of available land, it’s no surprise that agricultural operations are some of the most prominent economic contributors to this southern US state. In fact, it’s home to the highest number of ranches and farms, with an estimated 1.3 million acres of farmland.

But how are these agricultural operations able to provide this level of production? While most of it will come down to hard work, the right equipment, and determination, large metal buildings hold a special place in American farming. They’re incredibly strong, customizable, and among the most affordable construction methods on the market.

In this blog, we'll dive deeper into these versatile structures, how they're evolving, and what these changes mean for owning a metal building in Texas.

For years, metal buildings have been an inseparable part of commerce in the US. They’ve revolutionized how we manufacture goods and how business is done. And thanks to modern engineering practices, these structures are as popular as ever.

In fact, it’s estimated that roughly 95% of all industrial buildings utilize steel engineering. And there’s a reason for that. These buildings are strong, cost-effective, and can be built far faster than any competitive building type. They’re also highly adaptable, allowing businesses the freedom to configure them as necessary.

It is clear that 2020 was a year that changed everything for everyone across the globe. A pandemic being announced followed by a range of restrictions and changes to daily life meant that most of us faced a new type of uncertainty that we had never experienced before nor expected.

When you decide to purchase an RV, you will be making a significant investment that you are sure to want to get the most from. From traveling across the country for weekends away or taking longer trips, you can really make the most of your new home on wheels for many years to come.

However, protecting your RV when it is not in use is often something that people do not think about until after they’ve bought their RV. Rather than finding yourself without storage or choosing a solution that doesn’t work, we’ve shared the top five things you need to know before you buy an RV carport with storage so that you can purchase with confidence. Read on to find out more now.

The state of Arkansas has experienced over fifty major disasters in the last half-century. While it is not often directly hit by hurricanes, it experiences significant flooding, tornadoes, and other side effects of extreme weather. Because of this, Arkansas is ranked in the top ten states for natural disasters. With climate change increasing the number of major storms that hit the U.S. every year, this southern state faces a future with many obstacles. Businesses and customers in Arkansas will need strong, durable structures to provide safety in the upcoming decades.

November 15th is officially “America Recycles” Day, aka National Recycling Day. Are you ready to participate? In recent years, global nationalism has given way to global conservation, as citizens across the world join in preserving our most precious resources. From the Victorian-era dust collectors to the trendy zero-waste bloggers to the #BeRecycled, humanity is becoming more adept at reducing our footprint on our beloved planet. Of course, recycling is so much more than putting a bottle in the correct bin (though that’s a great place to start!). Let’s talk about how metal buildings can support your journey toward an eco-friendly lifestyle!

Prefabricated steel buildings have become popular because of their versatility and affordability. When you need a storage shed garage workshop or barn Coast to Coast Carports is the manufacturer to see. We lead the U.S. industry with the highest quality prefabricated steel buildings

In your search for Oregon steel buildings you have come to the right source. Coast to Coast Carports Inc. manufactures and sells steel buildings across the country - it’s not just in our name! Check out the many types of steel buildings available through our many dealers. We not only deal in carports

Coast to Coast Carports is the premiere Oregon metal buildings expert. We have years of steel building design and experience. We strive to produce only top quality products at the best possible prices. We offer personalized servic

Coast to Coast Carports offers a wide selection of storage buildings including carports garages utility buildings and metal storage building kits. They can accommodate any standard or custom steel building request. They have years of metal building experience and produce only the highest of quality products, all at very affordable prices.

Good Idaho steel buildings can be hard to come by. As an Idahoan you have needs that a lot of manufacturers just do not understand. A lot of companies try to get by without knowing their customers and this makes it so the equipment you buy does not work for Idaho’s environment.

The metal buildings New Mexico market can be difficult to navigate by yourself, which is why you can go to places like Coast to Coast Carports and find exactly what it is that you need in your new metal building.

Coast to Coast Carports has the steel building that you are looking for. We specialize in metal carports, metal barns, storage sheds, and custom steel buildings.

If concern over steel building prices is keeping you from adding a garage or storage shed to your property come see what we have to offer at Coast to Coast Carports Inc. "Carports" may be in our name but we specialize in constructing high-quality metal buildings of all types at affordable pr

A 30x40 metal building is a fairly standard size that can be used for a number of different purposes. They have ample room to serve as a double car garage. They're ideal for workshops of any kind and, with all that space, you can finally clean out the attic or basement to store the items you truly want to keep and still have room to spare. Metal buildings of this size are common and that's why we have them in stock and ready to go at Coast to Coast Carports.

Metal carports buildings barns and much more at Coast to Coast Carports is what we're known for. We build some of the finest carports and metal buildings in the lower 48. We custom build every carport do your specifications and needs finishing up with a beautiful design great looking metal

With over 15 years in business, Coast to Coast Carports continues to be the best metal carport company year after year. We specialize in constructing state of the art covered metal garages, barns, RV covers, and storage units. We oversee the entire process from start to finish. The result is a reliable, functional, and stylized metal carport that will provide shelter for years to come.

Year after year Coast-to-Coast Carports remains a leader in the market of metal building manufacturers. In business since 2001 Coast-to-Coast provides professional construction delivery and installation of RV covers and garages. Our services

Coast to Coast Carports custom builds and delivers quality American made prefab metal buildings that are stable secure and that can be delivered right to your property. Made from the best quality material money can buy our prefab metal bui

Running and operating a farm is an endeavor that has many moving parts. Constructing and maintaining high quality barns is just one necessary part. For many who are operating their own farms, constructing barns and buildings on the property is a major expensive, but it doesn’t have to be when you enlist the help of Coast-to-Coast Carports.

Though UV rays are a bigger threat to your boat than snow or freezing temperatures, the cold weather and frozen precipitation it brings can still cause significant damage. It is not simply a thermometer reading of 30 degrees or below, but a combination of moisture with low temperatures that can wreak havoc with a boat. Some people go to the expense of heated storage for their boats, but that is not always necessary. If you have properly winterized the motor and any other component that contains water to prevent freezing, you will not need heated storage. However, putting your boat under cover will provide protection it needs from snow.

Boats can have many different purposes. Some use them for fishing, others recreation, some transportation, and some people depend on them for their work. Boats can require quite a bit of maintenance and upkeep. Protecting your boat can help reduce the amount of maintenance and allow you to use your boat consistently without having to constantly worry about fixing it up.

Brand-new metal carports are something special for their owners. That beautiful gleaming metal looks like it could stand forever. And it can. But first it needs a little bit of protection first.

Prefab steel buildings are used for much more than just residential carports or garages. With high-quality galvanized steel, sturdy anchors, and additional bracing, metal buildings can easily be designed to withstand the harshest of weather conditions.

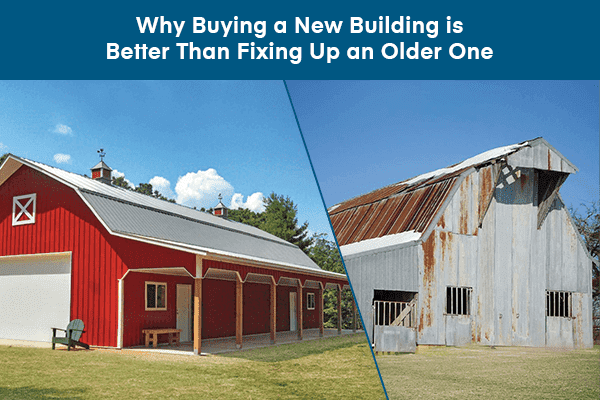

When you plan to buy a new building, no matter if it will be used for storage, parking, as a workshop, or a housing unit, steel structures are the best way to go. Pre-engineered metal buildings are custom-designed and manufactured to meet the needs of each individual. Not only can you have the structure tailored to your exact needs and your budget, but they can last for decades.

After spending your hard-earned money on a vehicle, you want the best protection for it, no matter its mileage or year model. And while you might have a garage currently installed on your property, they tend to be used more for storage than coverage for vehicles.

Buying a pre-engineered steel building for the first time can be exciting since you’re in a position where your business has grown, or you need additional space for your hobby. Yet, it can also be intimidating if you don’t have any experience designing your own or choosing a metal building for your needs.

Stick building is a traditional method of framing a home, barn, garage, or other building with lumber. Many builders and contractors still use this method, as wood is an easy material to custom cut and build with on site. There is also a lingering perception in the industry - as well as in the public eye - that stick-built homes and buildings are of higher quality than engineered structures.

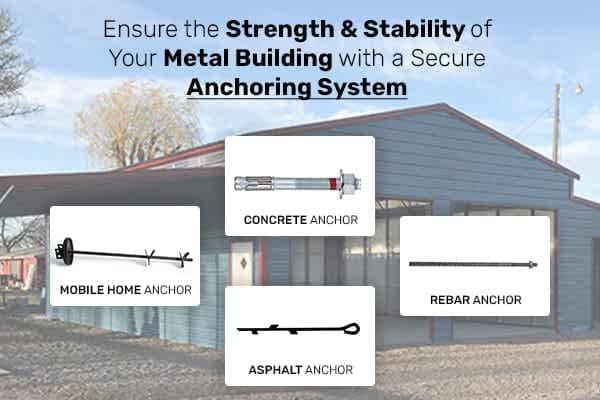

Choosing the perfect location for your outdoor steel structure is an important step to the process. You must make sure the site allows enough room, and more, for your structure to be installed. Be sure to check with your local ordinances regarding permits and local building codes BEFORE having your structure installed. The next step is to choose the foundation type: ground, gravel, asphalt, or concrete. Keep in mind that no matter what foundation type you choose, it must be level before assembly.

Steel Buildings have a diverse list of applications, from garages and storage facilities to residential and commercial uses. Long gone are the days when metal structures were used exclusively for sheltering things. People now live in these buildings or, at least, spend a significant time working in them. However, metals are good conductors. They will quickly heat up in summer and freeze during winter, making conditions very intolerable.

In October 2013, what was expected to be the average first snow of the season turned into a monster blizzard across the northern Great Plains. When the skies cleared and the snows melted, the cattle, horses, sheep, and bison that had been left unprotected or had been unable to be brought back from grazing on range lead to deaths nearing 43,000 head.

The countdown for Christmas has finally begun! Most people have already put their Christmas trees up, decorated their front yard with figurines and blow-ups, fixed the lights on their front porch, and wrapped all the presents. And while we know how fun it can be to prepare for this holiday season, we also understand how pricey it can be. But with these quick tips, you can have your house and your prefab steel building ready for Santa Claus in no time! And the best part? It can all be done on a budget!

So you’ve decided on your dream metal building and you’re ready to place an order. What should you do next? Coast to Coast Carports recommends that you must get familiar with the building permits and engineered plans.

Since the early 1600's, opera houses and theaters have been the place to go for a night of relaxation and entertainment. And as their popularity continues to rise, it's crucial that they can continue to provide Americans with an enjoyable night out on the town. Here at Coast to Coast Carports, we use the finest steel components for all our buildings, allowing them to stand strong and tall for years on end.

Stick building is a traditional method of framing a home, barn, garage, or other building with lumber. Many builders and contractors still use this method, as wood is an easy material to custom cut and build with on site. There is also a lingering perception in the industry - as well as in the public eye - that stick-built homes and buildings are of higher quality than engineered structures.

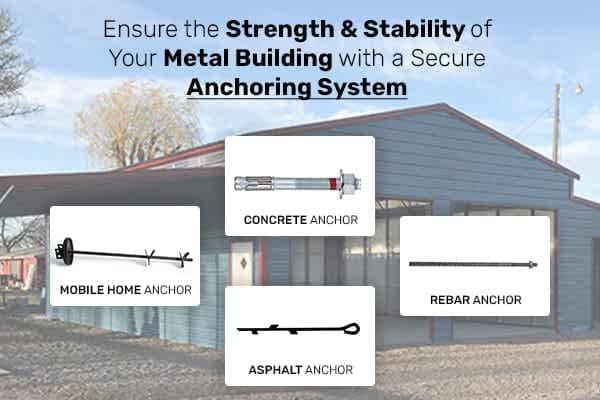

While steel is considered to be one of the strongest and longest lasting materials used in the metal building industry today it's overall sturdiness and strength rests upon its foundation and anchoring system. And if you don't follow the correct methods for anchor placement and installation you c

There is only one right answer to this question - however tall you want the building to be! Prefab steel buildings are also known as "low-rise", one story or two-story structures. And while many standard size, smaller buildings fall within a height range of 12' to 20', we've had some buildings reach up to 50', 80' and taller. If you're looking to invest in a higher clearance structure, additional planning may be required.

Despite your every effort, we know how easy it can be to run out of storage space in your home and garage. And while there are several storage options to take into consideration nowadays, a custom steel storage unit is the best way to go. No matter what your unique needs may be, there are various reasons as to why these are the best option for all your storage needs.

No matter where you go, chances are pretty high that you'll find at least one music venue or studio, even in the smallest town. But when you go to Tennessee, it's possible you'll find one on every corner.

Warehouses often get left out of the limelight and forgotten. They’re simply not as glamorous as their office and retail counterparts. For a while, these buildings were actually forgotten by a large part of the economy, too, but they have come roaring back in popularity in recent years thanks to several factors, including the booming business of e-commerce.

Do you want to design and install a metal building with metal roofing that will last up to 50 years? When you design a building with metal roofs you have to consider the site of your building create or buy designs and get approval. Of course you can then put the finishing touches on your purcha

Providing your prefab steel structure and personal property with adequate airflow can affect both the interior comfort of your unit as well as its overall durability. Proper ventilation systems can also help to prevent excessive moisture build-up, prolonging the lifespan of your metal building.

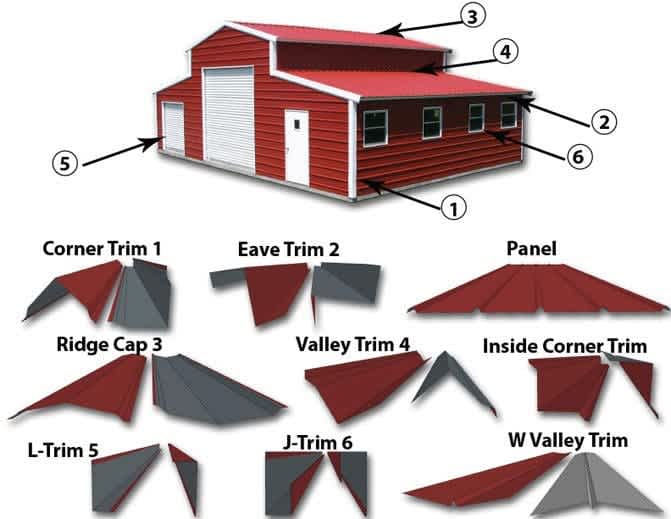

In addition to unique color combinations, there are several accessory options you can choose from to enhance the overall appeal and value of your structure. But by including accessories such as gutters, trim and eave flashings, you can enjoy more long-term benefits than increased value and aesthetic appeal.

When you start the journey of having a new metal building installed on your property, it’s important that you educate yourself on all building codes for your state, county, and city. Though it may not seem necessary at first, failing to meet these building codes could result in your project being suspended or torn down if it has been completed.

In order for you to avoid the worst case scenarios, you need to spend more time on finding the ideal site location to install your prefab steel barn. To help you make the right decision, here are a few things you will need to keep in mind.

When it comes to the integrity of your steel structure it’s crucial that you have all the knowledge needed to understand structural loads and how they effect buildings. And although every building material can be affected by these loads steel behaves quite differently when put under pressure.

With a prefab storage building, you can keep all your assets covered for a much lower price than a wooden structure. Built with high-quality, galvanized steel and the most up-to-date techniques, our steel storage buildings are designed specifically to fit virtually any need. From larger storage buildings for industrial uses, to smaller storage units for more residential needs, we have it all here at Coast to Coast Carports.

If your community has a Homeowners Association (HOA), you are more than likely bound to the written guidelines they’ve established for your area. These guidelines often cover items such as how many guests you can have at the community pool, where cars can be parked, the size of outdoor buildings on your property, etc.

For most people, being able to customize your very own steel building is a dream come true. Not only because you can finally bring your dream structure to life, but you can make it your very own. After choosing a metal building style that suits your needs and wants, you can continue the process by customizing the unit. The first step will be to choose an ideal color combination for the walls, trim and roof of your structure.

Investing in a building is a big commitment on many fronts. From weighing the financial cost against the possible return on investment to evaluating exactly what features you need your building to possess, the process of designing a building, taking the plunge, and purchasing it is sometimes monumental.

The United States is home to a wide variety of industries. It is truly the land of opportunity and full of ambitious industrious individuals. As your business evolves and grows having a suitable building to facilitate your work and the expansion of your needs is vital to sustained success.

Metal storage sheds have gained immense popularity in both residential and commercial settings due to their remarkable strength and adaptability. These structures offer a robust and durable solution for storing a wide range of items, from garden tools and equipment to commercial inventory and supplies. Their sturdy construction and resistance to weather conditions make them a reliable choice for long-term storage needs.

Industrial businesses have benefited from metal buildings for over a century. These buildings were tough, sturdy, and capable of taking on jobs that stick-built construction wouldn’t dare. But modern engineering techniques have given them a level of potential previously thought impossible.

Advances in the fabrication process allow steel buildings to be used in a wide range of applications. From commercial retail outlets to backyard sheds and residential homes, there are very few things metal structures can’t do.

In this blog, we'll explore a few unconventional ways metal buildings are used and how they might be the perfect investment for your residential, commercial, or industrial needs

Steel carports are a popular choice for protecting vehicles from the elements, and for a good reason! They’re strong and quite able to withstand harsh weather conditions and volatile climates. However, even though metal carports are built to endure the worst, they will still need occasional maintenance to ensure they remain in good condition.

In the following blog, we’ll walk you through several of the most effective ways of maintaining your steel carport. So if you’ve been searching for great cost-effective ways of keeping your new steel carport looking new, we’ve got you covered!

Auto repair shops have been a staple of American car culture for over a century. And with vehicles being a regular part of everyday life, it makes sense that these businesses are here to stay. In years past, these businesses were housed in traditional buildings such as brick, cinderblock, or wood. But thanks to modern engineering and manufacturing techniques, metal buildings are now one of the most versatile and affordable options for this business type. In fact, some estimates show that over 70% of all commercial auto repair businesses use large metal buildings for their infrastructure!

For years, commercial enterprises such as manufacturing facilities, warehouses, and large-scale retail stores have enjoyed the benefits steel buildings provide. These structures are incredibly strong, affordable, and can be built in a fraction of the time it takes to construct similar-sized wooden buildings.

They also offer a level of versatility not seen in other construction types, giving business owners free rein to design a structure to fit a business's specific needs. Combining this versatility with the unparalleled level of square footage clear span metal buildings offer, you have a recipe that works across almost any industry.

A steel garage may be an incredibly strong solution for housing your vehicles and supplies, but it won't be too effective without doors and windows. In addition to being necessary for ventilation and access, doors and windows will play a prominent role in how you can use your metal garage.

During the design process, you can easily add a few doors and windows and be done. But if you want the most out of your structure, you'll want to put some thought into the placement and location of these metal building components.

In this blog, we'll cover garage doors and windows on metal sheds and metal garages and how you can ensure you get the placement of your doors and windows right the first time.

Finding ample warehousing space in this day and age can be quite challenging for many business owners. In recent years, the cost of renting facilities for storage and distribution has increased tremendously, rising to prohibitively expensive rates. But as finding industrial-sized storage space becomes increasingly complex, there is a ray of hope for companies seeking cost-effective warehouse space. Prefab industrial metal warehouses are engineered for strength and customizability, providing businesses with the room and adaptability they need to operate.

Warehouses are a common sight in this day and age. Go through the right part of town, and you're bound to see a litany of them dotting the landscape. In years past, these buildings were either built from wood, concrete, or composites of the two. However, with modern advances, steel structures have become the go-to solution for a great majority of industrial applications. Clear span steel buildings are a type of metal structure that can be constructed at enormous sizes with no need for internal supports. This allows clear span buildings to provide unparalleled levels of square footage – perfect for owners and businesses that need ample room for storing inventory.

Did you know that more Americans than ever before are choosing to ditch their 9-5 lifestyle and hit the open road in an RV for at least some part of the year? The reasons for this are varied, with more remote working options, higher house prices, or an adventurous spirit being some of the most common causes. What is clear is that people want a change from the societal expectations and traditions that may currently be stifling them!

Loafing sheds were originally designed to provide a place for livestock to get access to straw and hay under cover, as well as to provide them with protection from the elements and somewhere to be housed. They are similar in size and usage to a stable and have been a popular building to have on farms across the United States.

The state of Arkansas isn’t known as The Natural State for nothing. It’s famous around the world for its rivers, hot springs, and lakes, as well as for its poultry and rice production. It’s also home to the US’s only active diamond mine. However, Arkansas has another natural feature that is sometimes overlooked. The state’s extreme weather conditions can cause a host of issues for its residents.

From the shining lights of Memphis to the beauty of the Cumberland Gap, Tennessee offers a wealth of opportunities and culture for visitors and residents. It’s hard to imagine how any one product could be useful in every walk of TN life; agriculture, industry, and commercial interests are all growing in the Volunteer State. Why are metal buildings becoming so popular in every part of Tennessee?

California is facing a climate crisis; wildfires, drought, and extreme temperatures have increasingly plagued the state since the mid-20th century. Climate scientists predict that these global warming events will continue to occur because of increased greenhouse gases caused by human activity. Even as global governments work to reverse the effects of climate change, CA residents must consider how to prepare for the future.

Thanksgiving is one of the most popular holidays in the US, with people taking the time to enjoy special time with the ones they love. Thanksgiving has evolved into the modern holiday we now enjoy, and the main characteristics of the day include a lot of food, delicious drinks, exciting football games, and massive parades, all shared with friends and family.

Every year, violent storms impact certain regions of the United States. If you live in states like Florida, Texas, Louisiana, North Carolina, Mississippi, Virginia, or any neighboring areas, you are also subject to harsh weather annually. This weather can have devastating effects on the areas it hits.

Hurricanes, tornadoes, intense thunderstorms, and lightning are all extreme conditions common to these areas. This is especially true for states located on the gulf coast like Florida. In this region, structural and flood damage to property from violent storms is not uncommon. Therefore, it is important to understand the risks of natural disasters and the potential danger they pose to your property.

Did you know that your metal building could increase the overall spread of disease or virus? While it may seem insane, it’s true. A prime example would be the recent outbreak of COVID-19, also known as the Coronavirus.

That is a question many of our customers ask us and themselves before they make a purchase. We will then reply with a few questions for them.

Metal tubing, panels, trim, and metal channel can be used for much more than just building Carports. Re-roof your home with metal roofing! Build an ultra strong metal fence out of square tubing. The possibilities are endless. If you only need panels, we can do that. If you only need some hat channel, we can do that. Give our sales department a call to find out more.

Whether you've got a business of your own or are just a backyard mechanic metal shop buildings from Coast to Coast Carports give you the space you need. The terrific thing about our metal buildings is that we can make any shop to your specifications. Not everyone needs a shop building to work on

Some business investments pay off for a few years and fade. Others just keep giving back. A commercial steel building falls into that second group. It’s a smart, practical move that makes sense long-term, no matter what type of project you're working on.

In most cases, you can expect to pay between $14 and $18 per square foot for a lean-to structure, depending on size and complexity. These lean-to structures are typically constructed as additions to an already present structure, making them an easy, cost-effective way to change the look and feel of your metal building.

As the second-largest US state, both in land and population, Texas is home to a wealth of industrial opportunities. It boasts a resilient economy, which experienced phenomenal growth through both the 2009 recession and the Covid-19 pandemic.

Every spring, homeowners are forced to account for tall grass, growing weeds, and outright ugly vegetation on their properties. If not handled regularly, these natural forces can transform a gorgeous property into an unsightly mess.

When purchasing a metal building for your home or business, one of the first questions you'll ask yourself is, 'How big do I need my structure to be?' While the question might seem simple on the surface, the choice you make can have a significant effect on your project and its final price tag. Steel buildings come in many shapes, sizes, and configurations, and finding the right one for your needs is crucial if you’re working on a budget and limited building space.

The secret is out– metal buildings are some of the most versatile buildings on the market and are engineered to handle some of the toughest jobs out there. As more and more Americans choose to invest in steel buildings for their homes, businesses, and farms, the demand for these prefab metal structures has grown exponentially.

Sometimes, you don't always have the luxury of a large backyard. In a world where space has become limited, many individuals struggle for space. But with a metal shed from Coast to Coast Carport, you can enjoy a high-quality structure that makes excellent use of your limited space.

When constructing a metal building, one of the biggest questions you'll ask yourself is whether to install insulation. If you expect to use your structure as a livable building or for anything other than simple storage, you'll likely need insulation.

No matter if you're part of the industry or have just heard about it, real estate is a rapidly growing business. And when industrial land properties are being maintained properly, they can produce quite a sizeable amount of money from one month to the next. While there are certain risks involved with the industrial real estate market, the advantages outweigh the disadvantages in the long run.

In most cases, you can expect a 30x40 metal building to cost between $20,000 and $40,000, depending on the manufacturer you go with and the customization options you choose. There are many metal building providers out there, all with varying prices and levels of quality.

As the old saying goes, a structure is only as good as the foundation on which it stands. And steel structures are no different! Despite these buildings being engineered for strength and flexibility in the face of high winds and heavy snowfall, if your foundation isn't up to snuff, you will have major issues for the life of your building.

If you’re building in a commercial space, there are many facets that you’ll need to cover, and one of those will undoubtedly be insurance. The rates charged by insurance companies will often vary based on the nature of the structure in question. Buildings constructed from materials that are more resistant to the leading causes of property damage will, on average, pay less for their premiums.

E-commerce giants are responsible for storing and moving huge amounts of inventory daily. To accomplish this, warehouses, fulfillment centers, and transportation hubs need ample amounts of unobstructed square footage to house inventory, equipment, and work vehicles.

Metal buildings are a popular choice for many businesses and homeowners. They are strong, durable, and can withstand violent weather conditions and heavy-duty use. But what truly sets them apart from the competition is their customizability. From top to bottom, almost every aspect of these incredible buildings can be tailored to your needs. And one such customization option is their doors.

If you intend to use your metal building for more than just seasonal applications, it’ll likely need insulation. Insulating your structure is a fantastic way to reduce moisture buildup and develop a more even internal temperature. But beyond that, it’s a necessary part of transforming your metal building from a simple shed into something more.

Insulation forms a barrier between the exterior elements and your building's interior. It holds in warmer are during the winter while allowing you to cut cooling costs during the summer months. It also prevents condensation from forming inside your building, which can be a significant issue for sensitive metal components such as fasteners and framing.

No matter what you intend to build, metal buildings have become a reliable construction option that opens up a wealth of opportunities in strength, design, and customizability. This makes them ideally suited for a vast array of applications, from backyard metal sheds to enormous commercial-grade steel buildings.

If you've been searching for the right solution to your storage or infrastructural woes, a metal building might be just what you need. In this blog, we'll explore these buildings in greater detail and show you how to use them to design a dream space that aligns with your lifestyle.

Metal buildings have become increasingly popular due to their durability and affordability. But, while metal structures are known for their strength, they are not always immune to the damaging effects of volatile weather. From spring storms to harsh winter winds, unprepared metal buildings can suffer significant damage if they are not designed to handle changing seasons.

That's why it's important to consider a metal building for sale specifically designed to withstand seasonal changes and weather conditions.

When it comes to business infrastructure, having the right setup is incredibly important. And a big part of that setup will be the design of your floor plan. This floor plan will dictate how you use your business and have a significant say in your productivity and longevity.

When it comes to finding extra space to store your belongings, why not consider using some of the room outside of your house? Installing metal carport kits or metal garage kits is a great way to get the room you need and combine it with a safe space to store your vehicle too.

Both types of kits are a great choice, but there are some fundamental differences between the two that may make one better than the other for your individual needs. Ultimately, metal garages come with sidewalls, a roof, and doors to create a fully enclosed space, whereas metal carports have open sides and a metal roof. If you are not sure which is the best choice for your needs, then we have created this comparison guide just for you – take a look now and then buy the right solution for your needs.

Metal Buildings and Carports come in an extensive array of sizes, shapes, and types. Some are simple outbuildings used to store your garden tools, while others might be large, fully finished homes. But what exactly makes a metal building permanent while others are not? We’re glad you asked!

Any outdoor building directly affixed to an unmoving foundation is classified as a permanent structure. Some examples of these structures include garages, barns, and even homes. Below, we’ll dive deeper into what differentiates these two classes of metal buildings and help you decide what is the better option for your needs.

If you’re familiar with gauging, you already know the golden rule – the lower the gauge number, the thicker the material. This is true for everything from pipes to earrings. And this principle is no different when it comes to the frame of prefab metal buildings. But what thickness should the framing on your structure be? Knowing what you need can be difficult if you're not immediately acquainted with steel buildings. So that's why we're here! Let's take a deeper dive into the world of metal buildings to help you find out what you need for your newest building project.

If you’ve ever owned a business, you already know that having the right infrastructure is extremely important to your workflow, finances, and income potential. This is why so many entrepreneurs have chosen steel buildings for their endeavors. These structures are incredibly strong, durable, and built to streamline your functionality.

A well-designed metal building foundation is the cornerstone of a reliable metal building. It serves as the support that holds your building up and an anchor system that holds it down. As such, taking the time to choose the right foundation will dictate much about how your structure performs.

People in Arkansas are frequently subjected to extreme weather, which can cause significant damage to buildings and businesses. As a result of this volatile climate, the region is seeing a growing demand for structures that can survive harsh weather while protecting their valuables from potential damage.

Metal buildings are an excellent option for Arkansas residents that need a structure capable of bearing intense loads withstanding high sustained winds. In this blog, we’ll explore these structures and explain why steel construction is one of the wisest ways to invest in your property.

If you're an avid traveler, owning an RV is an absolute dream come true. But, just like any cherished possession, you will need to keep your home on wheels safe and protected from the elements. That's where metal RV carports come to the rescue! These sturdy structures are a lifesaver, providing a reliable shield against rain, snow, hail, and harmful UV rays.

The beauty of metal RV carports lies not just in their practicality but also in their versatility. They come in many sizes and styles and can be configured to suit your specific needs. Whether you own a compact camper or a massive motorhome, a metal RV carport is ready to accommodate it like a snug blanket.

So, if you’re in the market for a way to protect your investment from harsh weather, UV rays, and potential thieves, keep reading to find out what type of metal RV carport is right for you.

One of the most important decisions you will make in regards to your metal building's design and structure will be the flooring and foundation you choose. For many, this decision comes down to the popularity, durability, and versatility of the foundation. That's why many buyers opt for concrete.

Take a stroll through your neighborhood downtown or retail district. Take special care to notice the buildings the wide variety of architectural styles and the broad selection of materials they use. With such diversity it's clear that you'll have seemingly endless options when it comes time to

Halloween is finally here! It’s a great chance to liven up the office with spooky decorations and the perfect excuse to drag out that old Prince costume. Whether you enjoy the ambiance, the snacks, and candy, or the ingenious costumes, Halloween is, without a doubt, one of the most festive office holidays.

Simply put, you can't go wrong with a 50x50 metal building. No matter the purpose or application, this structure can handle the job. These buildings provide significant space, making them ideal for a wide range of applications. Whether you need storage for equipment and machinery, a workshop for your business, or a spacious garage for your vehicles, a 50x50 metal building can get it done.

Florida is known for its tropical climate and volatile weather. From high winds to flooding, there is no shortage of elemental threats to contend with as a home and business owner. And as a result of the contentious weather, many folks have turned to metal buildings for their infrastructure. These structures are incredibly strong and engineered to handle just about any environment.

In recent years, pre-engineered steel buildings have emerged as an ideal choice for housing data centers, server farms, and cryptocurrency operations. These structures have proven to be a perfect fit for the unique demands of these industries, offering a host of advantages over traditional building materials. From strength to virtually endless customizability, there’s a reason these structures are one of the most popular choices for commercial construction.

In this blog, we'll explore exactly what custom metal buildings bring to the table for Bitcoin mining operations, crypto, and the future of American tech.

‘Clear span’ is an architectural term for the distance between the inner edges of span supports, i.e., the unsupported space. Steel buildings with clear spans offer a comprehensive and transparent surface free from posts and beams. There are no supporting pillars in a straightforward span design, as opposed to pole buildings.

Prefab metal buildings without columns or posts provide the most uninterrupted interior space. Steel buildings with a clear span are the best choice when maximum interior space is needed. Among the possible applications are:

The weather in Texas can certainly pose its fair share of problems. With hot and humid summers, and cold, windy, and dry winters, Texas’s climate is unusual.

During the year, the temperature can range between 36 degrees Fahrenheit and 96 degrees Fahrenheit. With such extremes, it isn’t surprising that the Lone Star State is the state with most disasters. Floods, ice storms, droughts, and tornadoes are all common here, and Hurricane Harvey wreaked havoc on the state in 2017. With all of this in mind, it isn’t too hard to see why a metal building in Texas is such a good idea. Metal garages and workshops withstand the humid, hot climate in Texas extremely well. They also resist natural disasters like tornadoes and hurricanes effectively when compared with other materials. When you need an outbuilding that is built to last, a metal workshop or metal garage in Texas is ideal.

A metal shed is a great way to add extra storage space to your home, farm, or business. These storage buildings come in many different sizes and styles and can be used for a wide range of purposes, from housing your lawn equipment to a workshop for your hobbies and side jobs.

However, before you start shopping for the perfect metal building, you should know a few things to ensure you get the best shed for your needs. So, if you’re searching for the best storage buildings for your needs, this blog is for you! So, let’s dive deeper into steel sheds and cover what you need to know to maximize your buying power!

Metal buildings are a significant investment! And if you're considering building one, you're probably wondering about the costs and how to budget for them. Metal building prices can vary widely depending on several factors, including size, location, and customization options. As such, it can be a challenge to nail an exact price. And even when you can, that price can literally change overnight.

But all is not lost! We can help! In this blog, we'll provide tips and guidance on budgeting for your metal building construction costs, so you can plan and prepare for your project. Whether you're looking to build a steel garage, workshop, or storage facility, these tips will help you make informed decisions and stay within your budget.

The state of Arkansas is a timber-rich region of the southern US that’s home to verdant forestland and gorgeous vistas. The region sits in an area of the country lovingly referred to as "America’s Wood Basket" due to the expansive forest land covering 20 million acres in the state. That’s nearly half of the state’s total land area! And of these numbers, roughly 11 million acres are privately owned by individuals and businesses.

If you’ve ever visited the Lonestar State, you already know that it’s a land of gorgeous blue skies, miles of farmland, and one of the largest economies in the world.

With a massive population and an unparalleled level of available land, it’s no surprise that agricultural operations are some of the most prominent economic contributors to this southern US state. In fact, it’s home to the highest number of ranches and farms, with an estimated 1.3 million acres of farmland.

But how are these agricultural operations able to provide this level of production? While most of it will come down to hard work, the right equipment, and determination, large metal buildings hold a special place in American farming. They’re incredibly strong, customizable, and among the most affordable construction methods on the market.

In this blog, we'll dive deeper into these versatile structures, how they're evolving, and what these changes mean for owning a metal building in Texas.

For years, metal buildings have been an inseparable part of commerce in the US. They’ve revolutionized how we manufacture goods and how business is done. And thanks to modern engineering practices, these structures are as popular as ever.

In fact, it’s estimated that roughly 95% of all industrial buildings utilize steel engineering. And there’s a reason for that. These buildings are strong, cost-effective, and can be built far faster than any competitive building type. They’re also highly adaptable, allowing businesses the freedom to configure them as necessary.

It is clear that 2020 was a year that changed everything for everyone across the globe. A pandemic being announced followed by a range of restrictions and changes to daily life meant that most of us faced a new type of uncertainty that we had never experienced before nor expected.

When you decide to purchase an RV, you will be making a significant investment that you are sure to want to get the most from. From traveling across the country for weekends away or taking longer trips, you can really make the most of your new home on wheels for many years to come.

However, protecting your RV when it is not in use is often something that people do not think about until after they’ve bought their RV. Rather than finding yourself without storage or choosing a solution that doesn’t work, we’ve shared the top five things you need to know before you buy an RV carport with storage so that you can purchase with confidence. Read on to find out more now.

The state of Arkansas has experienced over fifty major disasters in the last half-century. While it is not often directly hit by hurricanes, it experiences significant flooding, tornadoes, and other side effects of extreme weather. Because of this, Arkansas is ranked in the top ten states for natural disasters. With climate change increasing the number of major storms that hit the U.S. every year, this southern state faces a future with many obstacles. Businesses and customers in Arkansas will need strong, durable structures to provide safety in the upcoming decades.

November 15th is officially “America Recycles” Day, aka National Recycling Day. Are you ready to participate? In recent years, global nationalism has given way to global conservation, as citizens across the world join in preserving our most precious resources. From the Victorian-era dust collectors to the trendy zero-waste bloggers to the #BeRecycled, humanity is becoming more adept at reducing our footprint on our beloved planet. Of course, recycling is so much more than putting a bottle in the correct bin (though that’s a great place to start!). Let’s talk about how metal buildings can support your journey toward an eco-friendly lifestyle!

Prefabricated steel buildings have become popular because of their versatility and affordability. When you need a storage shed garage workshop or barn Coast to Coast Carports is the manufacturer to see. We lead the U.S. industry with the highest quality prefabricated steel buildings

In your search for Oregon steel buildings you have come to the right source. Coast to Coast Carports Inc. manufactures and sells steel buildings across the country - it’s not just in our name! Check out the many types of steel buildings available through our many dealers. We not only deal in carports

Coast to Coast Carports is the premiere Oregon metal buildings expert. We have years of steel building design and experience. We strive to produce only top quality products at the best possible prices. We offer personalized servic

Coast to Coast Carports offers a wide selection of storage buildings including carports garages utility buildings and metal storage building kits. They can accommodate any standard or custom steel building request. They have years of metal building experience and produce only the highest of quality products, all at very affordable prices.

Good Idaho steel buildings can be hard to come by. As an Idahoan you have needs that a lot of manufacturers just do not understand. A lot of companies try to get by without knowing their customers and this makes it so the equipment you buy does not work for Idaho’s environment.

The metal buildings New Mexico market can be difficult to navigate by yourself, which is why you can go to places like Coast to Coast Carports and find exactly what it is that you need in your new metal building.

Coast to Coast Carports has the steel building that you are looking for. We specialize in metal carports, metal barns, storage sheds, and custom steel buildings.

If concern over steel building prices is keeping you from adding a garage or storage shed to your property come see what we have to offer at Coast to Coast Carports Inc. "Carports" may be in our name but we specialize in constructing high-quality metal buildings of all types at affordable pr

A 30x40 metal building is a fairly standard size that can be used for a number of different purposes. They have ample room to serve as a double car garage. They're ideal for workshops of any kind and, with all that space, you can finally clean out the attic or basement to store the items you truly want to keep and still have room to spare. Metal buildings of this size are common and that's why we have them in stock and ready to go at Coast to Coast Carports.

Metal carports buildings barns and much more at Coast to Coast Carports is what we're known for. We build some of the finest carports and metal buildings in the lower 48. We custom build every carport do your specifications and needs finishing up with a beautiful design great looking metal

With over 15 years in business, Coast to Coast Carports continues to be the best metal carport company year after year. We specialize in constructing state of the art covered metal garages, barns, RV covers, and storage units. We oversee the entire process from start to finish. The result is a reliable, functional, and stylized metal carport that will provide shelter for years to come.

Year after year Coast-to-Coast Carports remains a leader in the market of metal building manufacturers. In business since 2001 Coast-to-Coast provides professional construction delivery and installation of RV covers and garages. Our services

Coast to Coast Carports custom builds and delivers quality American made prefab metal buildings that are stable secure and that can be delivered right to your property. Made from the best quality material money can buy our prefab metal bui

Running and operating a farm is an endeavor that has many moving parts. Constructing and maintaining high quality barns is just one necessary part. For many who are operating their own farms, constructing barns and buildings on the property is a major expensive, but it doesn’t have to be when you enlist the help of Coast-to-Coast Carports.

Though UV rays are a bigger threat to your boat than snow or freezing temperatures, the cold weather and frozen precipitation it brings can still cause significant damage. It is not simply a thermometer reading of 30 degrees or below, but a combination of moisture with low temperatures that can wreak havoc with a boat. Some people go to the expense of heated storage for their boats, but that is not always necessary. If you have properly winterized the motor and any other component that contains water to prevent freezing, you will not need heated storage. However, putting your boat under cover will provide protection it needs from snow.

Boats can have many different purposes. Some use them for fishing, others recreation, some transportation, and some people depend on them for their work. Boats can require quite a bit of maintenance and upkeep. Protecting your boat can help reduce the amount of maintenance and allow you to use your boat consistently without having to constantly worry about fixing it up.

Brand-new metal carports are something special for their owners. That beautiful gleaming metal looks like it could stand forever. And it can. But first it needs a little bit of protection first.

Prefab steel buildings are used for much more than just residential carports or garages. With high-quality galvanized steel, sturdy anchors, and additional bracing, metal buildings can easily be designed to withstand the harshest of weather conditions.

When you plan to buy a new building, no matter if it will be used for storage, parking, as a workshop, or a housing unit, steel structures are the best way to go. Pre-engineered metal buildings are custom-designed and manufactured to meet the needs of each individual. Not only can you have the structure tailored to your exact needs and your budget, but they can last for decades.

After spending your hard-earned money on a vehicle, you want the best protection for it, no matter its mileage or year model. And while you might have a garage currently installed on your property, they tend to be used more for storage than coverage for vehicles.

Buying a pre-engineered steel building for the first time can be exciting since you’re in a position where your business has grown, or you need additional space for your hobby. Yet, it can also be intimidating if you don’t have any experience designing your own or choosing a metal building for your needs.

Stick building is a traditional method of framing a home, barn, garage, or other building with lumber. Many builders and contractors still use this method, as wood is an easy material to custom cut and build with on site. There is also a lingering perception in the industry - as well as in the public eye - that stick-built homes and buildings are of higher quality than engineered structures.

Choosing the perfect location for your outdoor steel structure is an important step to the process. You must make sure the site allows enough room, and more, for your structure to be installed. Be sure to check with your local ordinances regarding permits and local building codes BEFORE having your structure installed. The next step is to choose the foundation type: ground, gravel, asphalt, or concrete. Keep in mind that no matter what foundation type you choose, it must be level before assembly.